This is a follow-up to my last post on Hands-On Winemaking. Last September I put up a post on my Westwood blog where I attempted to define my personal winegrowing philosophy as "Pre-Emptive Minimalism".

In a nutshell, following this approach means to 1) do nothing I don't have to, and 2)to do nothing that forces me to do extra work later. In the context of the last post I would call this "Interventionist Minimalism" in contrast to minimal intervention.

Friday, June 27, 2008

Saturday, June 14, 2008

Hands-On Winemaking

My friend Greg Snell recently posted to his blog about "non-interventionist" winemaking and the WinePod. I will take this opportunity to weigh in on the subject.

What on earth does someone mean when they talk about "non-interventionist winemaking"? Where did this term come from? I'm not the first person to ask these questions. Check out Eric Asimov's piece in the NY times from October 2006. I think it may be that the term first arose in the film "Mondovino" which, for dramatic effect, built its narrative around the differences between the "...old world and new, simple peasants and billionaires, and between the local and artisanal styles of wine production and the multinational and mass-produced ones."

Award-winning New Zealand winemaker and writer Drew Tuckwell put it as succinctly as such a vague and useless concept might possibly be clarified: "Non interventionist winemaking is not easy to explain. There are no defined or common rules. It is essentially a very natural form of winemaking ... where, in general terms, winemakers resist the use of modern technology and simply allow the wines to express the terroir of the vineyard." (1) Emphasis mine.

My sainted Dallas-bred grandmother had a term for this kind of marketing-speak: "horse-puckey".

The craft of winemaking is the transformation of grapes with alchemist skill. For centuries the French have applied the terms "elevage" and "affinage" to the winemaking process. The winemaker facilitates the birth of the wine, and then raises it and refines it into something which, if not always transcendent and sublime, is at least palatable. I believe the most apt analogy for winemaking is child-rearing. I for one don't believe that child rearing can be at all non-interventionist. And neither can winemaking be.

I shall step on a slightly taller soapbox to proclaim: I believe that ALL wines – artisanal and mass-produced alike – are valid expressions of the grape, and of the winemaker's craft. There is no way to define a cutoff between these arbitrary classifications; wines are produced along a technological contiuum.

On the other hand, all wines are not created equal. There are distinctions between the aromas and tastes of wines made by hand and those produced by machine that are no more arbitrary or subtle than the differences between, say, Redwood Hill Farm crottin and processed American cheese spread, or Boont Amber Ale and Bud. But there is no doubt that the makers of the crottin and the ale are interventionist to a fault in crafting their products. So are ALL winemakers worthy of the title.

For contrast, let me paint a scenario of the least-interventionist winemaking I can imagine. Find some grapes – they must be wild, or escapees from cultivation, un-pruned and otherwise un-farmed. Pay no attention to the mildew, bird damage and rot. Taste them to see if they are ripe, and try to forget that professionals with decades of experience sometimes misjudge ripeness by taste. Pick them anyway.

Put these natural wonders in a garbage pail in the garage – don't worry if the pail is clean or not, or how hot or cold the space is. Intervene to the extent of crushing the grapes by foot. Step away at this point, intervention complete – the grapes will ferment. But at least go so far as to cover the pail before turning out the lights. Come back in a month or so, lift the pail and make a small hole in the bottom for the liquid to drain out. Intervene again to push on the mass inside the pail to press as much liquid out as possible. Collect, taste and savor.

I can say from personal experience that the results will not be palatable.

I can also say that there is not a capital-poor winemaker worth the title that has not wished for a centrifuge (for clarification), a spinning cone (for alcohol reduction), or for ion-exchange (to remove volatile acidity) at some point in their career. In my opinion, any winemaker that can say they are "non-interventionist" with a straight face, or at least without a little lurch of self-loathing in the pit of the stomach, is a charlatan or worse – delusional.

Given the choice between a garbage pail and the WinePod, I'll take the Pod thanks. I can make better wine in the WinePod. Doesn't make me a mass-producer – the wines are still hand-made. Just don't call me "non-interventionist".

What on earth does someone mean when they talk about "non-interventionist winemaking"? Where did this term come from? I'm not the first person to ask these questions. Check out Eric Asimov's piece in the NY times from October 2006. I think it may be that the term first arose in the film "Mondovino" which, for dramatic effect, built its narrative around the differences between the "...old world and new, simple peasants and billionaires, and between the local and artisanal styles of wine production and the multinational and mass-produced ones."

Award-winning New Zealand winemaker and writer Drew Tuckwell put it as succinctly as such a vague and useless concept might possibly be clarified: "Non interventionist winemaking is not easy to explain. There are no defined or common rules. It is essentially a very natural form of winemaking ... where, in general terms, winemakers resist the use of modern technology and simply allow the wines to express the terroir of the vineyard." (1) Emphasis mine.

My sainted Dallas-bred grandmother had a term for this kind of marketing-speak: "horse-puckey".

The craft of winemaking is the transformation of grapes with alchemist skill. For centuries the French have applied the terms "elevage" and "affinage" to the winemaking process. The winemaker facilitates the birth of the wine, and then raises it and refines it into something which, if not always transcendent and sublime, is at least palatable. I believe the most apt analogy for winemaking is child-rearing. I for one don't believe that child rearing can be at all non-interventionist. And neither can winemaking be.

I shall step on a slightly taller soapbox to proclaim: I believe that ALL wines – artisanal and mass-produced alike – are valid expressions of the grape, and of the winemaker's craft. There is no way to define a cutoff between these arbitrary classifications; wines are produced along a technological contiuum.

On the other hand, all wines are not created equal. There are distinctions between the aromas and tastes of wines made by hand and those produced by machine that are no more arbitrary or subtle than the differences between, say, Redwood Hill Farm crottin and processed American cheese spread, or Boont Amber Ale and Bud. But there is no doubt that the makers of the crottin and the ale are interventionist to a fault in crafting their products. So are ALL winemakers worthy of the title.

For contrast, let me paint a scenario of the least-interventionist winemaking I can imagine. Find some grapes – they must be wild, or escapees from cultivation, un-pruned and otherwise un-farmed. Pay no attention to the mildew, bird damage and rot. Taste them to see if they are ripe, and try to forget that professionals with decades of experience sometimes misjudge ripeness by taste. Pick them anyway.

Put these natural wonders in a garbage pail in the garage – don't worry if the pail is clean or not, or how hot or cold the space is. Intervene to the extent of crushing the grapes by foot. Step away at this point, intervention complete – the grapes will ferment. But at least go so far as to cover the pail before turning out the lights. Come back in a month or so, lift the pail and make a small hole in the bottom for the liquid to drain out. Intervene again to push on the mass inside the pail to press as much liquid out as possible. Collect, taste and savor.

I can say from personal experience that the results will not be palatable.

I can also say that there is not a capital-poor winemaker worth the title that has not wished for a centrifuge (for clarification), a spinning cone (for alcohol reduction), or for ion-exchange (to remove volatile acidity) at some point in their career. In my opinion, any winemaker that can say they are "non-interventionist" with a straight face, or at least without a little lurch of self-loathing in the pit of the stomach, is a charlatan or worse – delusional.

Given the choice between a garbage pail and the WinePod, I'll take the Pod thanks. I can make better wine in the WinePod. Doesn't make me a mass-producer – the wines are still hand-made. Just don't call me "non-interventionist".

Saturday, June 7, 2008

Catching Up With The Roberts Road Pinot

The Sangiacomo Roberts Road Pinot lot finally completed alcoholic fermentation after the re-inoculation on 4/7.

My personal cutoff for "doneness" on alcoholic fermentation is 1.00 g/L, though I prefer to see on the order of 1/10th that number before I inoculate for malolactic – which is sort of what I did.

On 5/15/08 I inoculated the Pinot in barrel and carboy with 2.5 grams of Enoferm Alpha malolactic culture, prepared according to directions.

| glu+fru | malic | ||

| 03/28/08 | 3.94 | 1.33 | g/L |

| 04/03/08 | 3.05 | ---- | g/L |

| 04/14/08 | 1.18 | 1.22 | g/L |

| 05/02/08 | 0.20 | 1.09 | g/L |

On 5/15/08 I inoculated the Pinot in barrel and carboy with 2.5 grams of Enoferm Alpha malolactic culture, prepared according to directions.

Thursday, June 5, 2008

Finishing Off The Syrah Fermentation

May was a very busy month for me and I was not able to devote the time I wanted to maintaining this blog. It is time to catch up and so this is likely to be a long post.

I pressed off the Annadel Syrah on 5/1/08 after a full 30 days of maceration at elevated temperature (73° F) – if there was a question in anyone's mind, it was my intention to see how far I could push this protocol.

Jumping ahead a little, in my opinion the wine turned out very well, analytically and organoleptically. So since I didn't "break it" with a full month of maceration I can't say that I have pushed the procedure to its absolute limit. But what I learned is that I can be more sanguine about recommending longer maceration in the Pod – at least up to this now-defined point, and with these grapes.

I pressed the Syrah as I have the other lots: first with automatic pressing on the "heavy" setting (present on this Pod beta unit – likely not on shipping units) until done, then on manual every minute, then every 2 minutes, then every 5 minutes, until the press shuts off immediately on startup. Also as before, I racked the wine from the Pod into buckets, cleaned the Pod, and racked the wine back in. The yield was about 11 gallons. I set the temperature of the Pod to 65° F.

I pulled a sample for the lab; results of the analysis:

My personal threshold for malolactic "doneness" is 0.30 g/L so this wine is done enough. The V.A. has crept up a tiny bit since the end of alcoholic fermentation (from 0.26 g/L – almost within analytical error) supporting that the long extension of maceration didn't oxidize the wine appreciably. From a philosophical standpoint the pH is higher than I want it to be, though the wine does not taste fat, soapy, or bitter.

On 5/4/08 I set the temperature of the Pod to 60° F. The next day I stirred in 20 grams of tartaric acid (0.5 g/L) and 5 grams of Efferbaktol granules (about 48 ppm of SO2).

The Syrah settled in the Pod at 60° F for nearly two weeks. On 5/16/08 I racked the wine to glass carboys (7, 2 and 1 gallon) with the extra going into two 750 mL bottles. Total yield of clear wine after racking was 10.4 gallons.

In my commercial wine production I have found that Syrah benefits from spending some time in tank after the first racking, before going to barrels. It is my intention to leave this WinePod Syrah in glass for a while before I put it into wood.

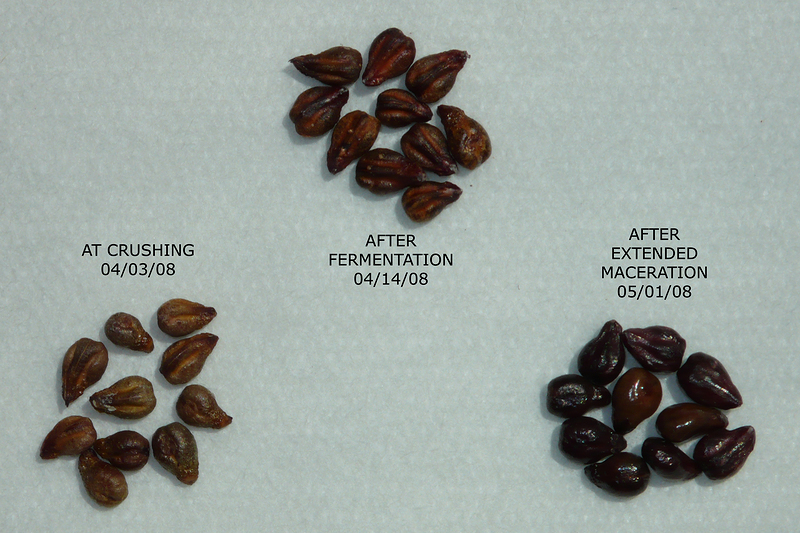

Another thing I wanted to do with this Syrah ferment was collect seeds to illustrate the changes that occur during extended maceration.

The seeds in the middle were pulled from inside berries at the end of the yeast fermentation. Notice that they are darker and redder, but not uniformly colored.

The seeds on the right were removed from berries in the press cake after taking it out of the Pod. Notice how they have turned darker, and though not all of them are exactly the same dark shade the color is uniform on each. These are the visual qualities I look for in the seeds on completion of extended maceration.

I pressed off the Annadel Syrah on 5/1/08 after a full 30 days of maceration at elevated temperature (73° F) – if there was a question in anyone's mind, it was my intention to see how far I could push this protocol.

Jumping ahead a little, in my opinion the wine turned out very well, analytically and organoleptically. So since I didn't "break it" with a full month of maceration I can't say that I have pushed the procedure to its absolute limit. But what I learned is that I can be more sanguine about recommending longer maceration in the Pod – at least up to this now-defined point, and with these grapes.

I pressed the Syrah as I have the other lots: first with automatic pressing on the "heavy" setting (present on this Pod beta unit – likely not on shipping units) until done, then on manual every minute, then every 2 minutes, then every 5 minutes, until the press shuts off immediately on startup. Also as before, I racked the wine from the Pod into buckets, cleaned the Pod, and racked the wine back in. The yield was about 11 gallons. I set the temperature of the Pod to 65° F.

I pulled a sample for the lab; results of the analysis:

| pH | 3.94 | |

| Malic Acid | 0.13 | g/L |

| Volatile Acidity | 0.38 | g/L |

On 5/4/08 I set the temperature of the Pod to 60° F. The next day I stirred in 20 grams of tartaric acid (0.5 g/L) and 5 grams of Efferbaktol granules (about 48 ppm of SO2).

The Syrah settled in the Pod at 60° F for nearly two weeks. On 5/16/08 I racked the wine to glass carboys (7, 2 and 1 gallon) with the extra going into two 750 mL bottles. Total yield of clear wine after racking was 10.4 gallons.

In my commercial wine production I have found that Syrah benefits from spending some time in tank after the first racking, before going to barrels. It is my intention to leave this WinePod Syrah in glass for a while before I put it into wood.

Another thing I wanted to do with this Syrah ferment was collect seeds to illustrate the changes that occur during extended maceration.

Click on the image above for larger 800 px image

Click on the image above for larger 800 px image

The seeds in the middle were pulled from inside berries at the end of the yeast fermentation. Notice that they are darker and redder, but not uniformly colored.

The seeds on the right were removed from berries in the press cake after taking it out of the Pod. Notice how they have turned darker, and though not all of them are exactly the same dark shade the color is uniform on each. These are the visual qualities I look for in the seeds on completion of extended maceration.

Tuesday, April 22, 2008

Syrah - All Is Well

Extended maceration continues at 73° F on the Annadel Syrah. The Pod is reading -5° Brix suggesting that the sensor is stuck to the bottom of the tank. Malolactic fermentation is producing enough carbon dioxide at this time to keep the cap floating. Yesterday I popped two more gas cartridges under the Pod lid anyway – one of them was unmarked and turned out to be CO2.

Saturday, April 19, 2008

Syrah Cap Back Up

Yesterday when I checked the Syrah I found that the malolactic ferment was producing enough gas to bring the cap back up. I gave the must a mix (#14) and then shot some nitrogen into the headspace using two of the gas cartridges supplied with the Pod.

These cartridges each supply 1.8 g of N2. Dredging up some freshman general chemistry from memory, this comes to about 1.44 liters of gas (at STP) per cartridge.

I have not made an exact measurement but I'm guessing the headspace is more like 4-5 gallons, meaning it would take about 12 cartridges to purge this volume with nitrogen.

If the cap falls again before the tannins have softened I will probably fit the variable-capacity lid to the Pod.

These cartridges each supply 1.8 g of N2. Dredging up some freshman general chemistry from memory, this comes to about 1.44 liters of gas (at STP) per cartridge.

I have not made an exact measurement but I'm guessing the headspace is more like 4-5 gallons, meaning it would take about 12 cartridges to purge this volume with nitrogen.

If the cap falls again before the tannins have softened I will probably fit the variable-capacity lid to the Pod.

Wednesday, April 16, 2008

Inoculated 2007 Syrah for Malolactic

Following my temperature plan I dropped the lower setpoint on the ferment to 73° F by Saturday the 12th (punch #11). The must reading was -3° Brix.

At punch #12 on Monday the 14th I observed the second must reading at -3° Brix, so I pulled a sample for analysis and recovered some seeds which I will use in my photographic comparison after I press this lot off.

Results of the analysis of the Syrah sample:

This confirms that the wine is bone-dry.

Since the wine is dry, today I prepared 2.5 g of Enoferm Alpha malolactic culture according to directions and inoculated the must at punch #13. It is still my plan to extend the maceration until April 30th – the wine is tasting quite tannic at the moment – but the cap has already lost much of its buoyancy. It may regain some if the malolactic fermentation produces a little CO2 (in my experience sometimes it does, sometimes not) but with this ferment I am thinking I will be sparging the headspace with inert gas before I get to pressing.

At punch #12 on Monday the 14th I observed the second must reading at -3° Brix, so I pulled a sample for analysis and recovered some seeds which I will use in my photographic comparison after I press this lot off.

Results of the analysis of the Syrah sample:

| Alcohol | 14.72 | % (v/v) |

| pH | 3.79 | |

| Titratable Acidity | 6.56 | g/L |

| Malic Acid | 1.56 | g/L |

| Glucose+Fructose | 0.05 | g/L |

| Volatile Acidity | 0.26 | g/L |

Since the wine is dry, today I prepared 2.5 g of Enoferm Alpha malolactic culture according to directions and inoculated the must at punch #13. It is still my plan to extend the maceration until April 30th – the wine is tasting quite tannic at the moment – but the cap has already lost much of its buoyancy. It may regain some if the malolactic fermentation produces a little CO2 (in my experience sometimes it does, sometimes not) but with this ferment I am thinking I will be sparging the headspace with inert gas before I get to pressing.

Thursday, April 10, 2008

Syrah Ferment Peak

Yesterday evening the must readings were 15° Brix at 81° F. At punch #7 I added another 15 g of DAP dissolved in 150 mL warm water and increased the lower setpoint to 86° F.

This morning the Pod was showing 6° Brix at 85° F. I made the third and final 15 g DAP addition at the punchdown. I plan to start dropping the temperature at this evening's punch.

Knock on wood – this fermentation is textbook (so far). Total DAP addition was the maximum allowable 1 g/L, and the must has smelled really good all along, with only hints of sulfide.

I want to note that this ferment has not once threatened to overflow the Pod. The Lallzyme products are a mix of cellulases and hemicellulases (with very low glycosidase side activity – important to maintain the color and aromatic potential of a red wine) which hydrolyze the grape cell walls and do a good job of breaking down the cap.

At this time I am planning to bring the temperature down to 73° F by Saturday the 12th. This is the temperature where I expect to maintain this lot through extended maceration. Sometime in the week of the 14th I will test for residual sugar – when it is below the 1 g/L threshold I will inoculate for malolactic. I hope to press on the 30th.

This morning the Pod was showing 6° Brix at 85° F. I made the third and final 15 g DAP addition at the punchdown. I plan to start dropping the temperature at this evening's punch.

Knock on wood – this fermentation is textbook (so far). Total DAP addition was the maximum allowable 1 g/L, and the must has smelled really good all along, with only hints of sulfide.

I want to note that this ferment has not once threatened to overflow the Pod. The Lallzyme products are a mix of cellulases and hemicellulases (with very low glycosidase side activity – important to maintain the color and aromatic potential of a red wine) which hydrolyze the grape cell walls and do a good job of breaking down the cap.

At this time I am planning to bring the temperature down to 73° F by Saturday the 12th. This is the temperature where I expect to maintain this lot through extended maceration. Sometime in the week of the 14th I will test for residual sugar – when it is below the 1 g/L threshold I will inoculate for malolactic. I hope to press on the 30th.

Wednesday, April 9, 2008

Annadel Syrah Ferment Taking Off

After inoculating the must Monday morning, the cap was barely up Tuesday morning – not solid, sort of half-hearted. It was a little firmer at the afternoon punchdown (punch #5). I raised the setpoints at each visit – the lower from 69° to 72° F, and from 72° to 78° F in the afternoon.

Note that I have settled on a span of 3°F for determining the upper setpoint – I will only be reporting the lower setpoint going forward. The must read 24° Brix at both punchdowns.

This morning the cap was solid and the Pod was reporting 20° Brix at 77° F. I dissolved/suspended 8 g Fermaid K (19 g/hL or 1.6#/M – note that the maximum addition rate for this product is 2#/M) and 15 g DAP (0.33 g/L) in about 200 mL warm water and added this at the punch. This is the first of three planned DAP additions. Upped the setpoint to 80° F.

Though I peaked the Pinot fermentation at 92° F my plan for the Syrah is to peak this ferment at 86° F as I did for the two Cabernet lots.

Note that I have settled on a span of 3°F for determining the upper setpoint – I will only be reporting the lower setpoint going forward. The must read 24° Brix at both punchdowns.

This morning the cap was solid and the Pod was reporting 20° Brix at 77° F. I dissolved/suspended 8 g Fermaid K (19 g/hL or 1.6#/M – note that the maximum addition rate for this product is 2#/M) and 15 g DAP (0.33 g/L) in about 200 mL warm water and added this at the punch. This is the first of three planned DAP additions. Upped the setpoint to 80° F.

Though I peaked the Pinot fermentation at 92° F my plan for the Syrah is to peak this ferment at 86° F as I did for the two Cabernet lots.

Monday, April 7, 2008

Annadel Syrah Inoculation

When I arrived at the winery this morning the Pod readings were 25° Brix at 65° F. I intended to raise the setpoints a small amount but mis-read my own chart and punched in the setpoints I had planned to hit in the afternoon: 69° and 72° F. Eh. No big deal.

I prepped 13 g of GoFerm in 200 mL distilled water at 104° F, and stirred in 11 g of Uvaferm 43 yeast. I waited 20 minutes and then "proofed" the yeast prep with about a gram of sucrose dissolved in a little warm water.

After the yeast prep started to bubble I pitched it into the Syrah, mixed for the third time, and put the lid back on.

I prepped 13 g of GoFerm in 200 mL distilled water at 104° F, and stirred in 11 g of Uvaferm 43 yeast. I waited 20 minutes and then "proofed" the yeast prep with about a gram of sucrose dissolved in a little warm water.

After the yeast prep started to bubble I pitched it into the Syrah, mixed for the third time, and put the lid back on.

Roberts Road Pinot Re-Inoculation

Since the Pinot in barrel is only fermenting sugar at a rate less than 1 g/L/week I decided to help things along.

First, I topped the wine with 1.75 liters of water. This should take the alcohol from 15.1% to 14.2%.

Then I weighed out 63 g of RC212, the yeast I used to ferment the must in the first place. This rate of yeast addition is about 150 g/hL or six times the normal recommended rate. In my experience the rate of addition for re-inoculation needs to be at least 100 g/hL. A rate of 200 g/hl is overkill for all but the most stubborn stuck ferments. I dissolved the RC212 in 630 mL of distilled water at 104° F and waited 20 minutes.

I might otherwise have used Uvaferm 43, the absolute "best" yeast for restarting a stuck ferment, but I didn't have 63 g of Uva43, and this wine is just "barely stuck".

After 20 minutes I stirred into the yeast mixture 2 g sucrose (table sugar) dissolved in a small volume of hot water. This is important. The sugar addition brought the yeast mixture to 3 g/L – about the same as the wine. The rehydrated yeast started to bubble moderately.

While the yeast was rehydrating I pulled about 920 mL wine from the 30 L barrel and 340 mL from the 11 L carboy (1260 mL total). I poured half this volume into a clean 1/2-gallon jug and set it in a warm water bath to raise the temperature of the wine.

When the wine had warmed to 80° F, and the yeast mixture cooled to 90° F, I poured most of the yeast prep into the jug and put a fermentation lock on top. The mixture started to bubble immediately.

I transferred the remaining 630 mL of wine to the leftover yeast prep, stirred, and poured into a clean 750 mL screw-top bottle. This mixture also started producing bubbles immediately.

So far so good.

I took both the jug and the bottle with me to the office, and left them in my car to keep them warm. In retrospect I should have exercised a little more caution with where I placed them in the car. When I returned 6 hours later both were in the sun and warmer than I wanted. I would have been happiest if they had stayed at 80° F but both were measuring 100° F when I got back to the winery. Both were still producing bubbles, so my hope is that the yeast weren't completely killed.

Nota bene: alcohol plus high temperature equals dead yeast.

Anyway, I pitched the yeast prep from the 1/2-gallon jug into both the barrel and the carboy to top, and both started to show some signs of bubbles rising to the surface. I will take a sample to the lab in a few days to see if this restart was successful.

First, I topped the wine with 1.75 liters of water. This should take the alcohol from 15.1% to 14.2%.

Then I weighed out 63 g of RC212, the yeast I used to ferment the must in the first place. This rate of yeast addition is about 150 g/hL or six times the normal recommended rate. In my experience the rate of addition for re-inoculation needs to be at least 100 g/hL. A rate of 200 g/hl is overkill for all but the most stubborn stuck ferments. I dissolved the RC212 in 630 mL of distilled water at 104° F and waited 20 minutes.

I might otherwise have used Uvaferm 43, the absolute "best" yeast for restarting a stuck ferment, but I didn't have 63 g of Uva43, and this wine is just "barely stuck".

After 20 minutes I stirred into the yeast mixture 2 g sucrose (table sugar) dissolved in a small volume of hot water. This is important. The sugar addition brought the yeast mixture to 3 g/L – about the same as the wine. The rehydrated yeast started to bubble moderately.

While the yeast was rehydrating I pulled about 920 mL wine from the 30 L barrel and 340 mL from the 11 L carboy (1260 mL total). I poured half this volume into a clean 1/2-gallon jug and set it in a warm water bath to raise the temperature of the wine.

When the wine had warmed to 80° F, and the yeast mixture cooled to 90° F, I poured most of the yeast prep into the jug and put a fermentation lock on top. The mixture started to bubble immediately.

I transferred the remaining 630 mL of wine to the leftover yeast prep, stirred, and poured into a clean 750 mL screw-top bottle. This mixture also started producing bubbles immediately.

So far so good.

I took both the jug and the bottle with me to the office, and left them in my car to keep them warm. In retrospect I should have exercised a little more caution with where I placed them in the car. When I returned 6 hours later both were in the sun and warmer than I wanted. I would have been happiest if they had stayed at 80° F but both were measuring 100° F when I got back to the winery. Both were still producing bubbles, so my hope is that the yeast weren't completely killed.

Nota bene: alcohol plus high temperature equals dead yeast.

Anyway, I pitched the yeast prep from the 1/2-gallon jug into both the barrel and the carboy to top, and both started to show some signs of bubbles rising to the surface. I will take a sample to the lab in a few days to see if this restart was successful.

Sunday, April 6, 2008

Syrah Additions

Yesterday when I checked the Pod it was reading 25° Brix at 51° F. I increased the setpoints to 58° and 61° F. I have never seen any positive effect of pre-fermentation maceration on Syrah, so I plan to increase the temperature on a regular slope.

Today the must readings were 25° Brix at 58° F. Color and aroma of the juice were lovely. I made an addition of 1.8 g Lallzyme EX, giving an addition rate of about 3 g/100 kg of fruit – the maximum recommended rate for this particular enzyme product. I have found that the addition of enzyme is most important when fermenting in the Pod to help avoid overflowing the tank.

After I added the Lallzyme I set the temparature control points to 63° and 66° F and mixed. Then I made tannin additions.

I prepared a solution of 10 g Laffort VR Supra (Quebracho), 4 g Vialatte Sublitan Vinif (grape seed), and 2 g Vialatte Oenotan (oak) in one liter of water, and mixed it thoroughly into the must.

Next I prepared a solution of 25 g tartaric acid in one liter of water and mixed it into the must as well. As with the three ferments that have gone before, I feel this 0.5 g/L pre-fermentation addition of tartaric is a good starting point to end up with a "reasonable" post-fermentation pH.

Post-mixing I measured the dissolved solids with a digital refractometer and found that the must was reading 25.1° Brix after incorporating about 3.5 liters of water with these various additions.

Before closing up the Pod for the day I squeezed the seeds out of a number of berries, rinsed them and dried them by rubbing between paper towel to remove attached pulp. Then I photographed them before putting them into a labeled baggie. The plan is to compare the appearance of seeds before fermentation, at dryness, and at the end of extended maceration.

Today the must readings were 25° Brix at 58° F. Color and aroma of the juice were lovely. I made an addition of 1.8 g Lallzyme EX, giving an addition rate of about 3 g/100 kg of fruit – the maximum recommended rate for this particular enzyme product. I have found that the addition of enzyme is most important when fermenting in the Pod to help avoid overflowing the tank.

After I added the Lallzyme I set the temparature control points to 63° and 66° F and mixed. Then I made tannin additions.

I prepared a solution of 10 g Laffort VR Supra (Quebracho), 4 g Vialatte Sublitan Vinif (grape seed), and 2 g Vialatte Oenotan (oak) in one liter of water, and mixed it thoroughly into the must.

Next I prepared a solution of 25 g tartaric acid in one liter of water and mixed it into the must as well. As with the three ferments that have gone before, I feel this 0.5 g/L pre-fermentation addition of tartaric is a good starting point to end up with a "reasonable" post-fermentation pH.

Post-mixing I measured the dissolved solids with a digital refractometer and found that the must was reading 25.1° Brix after incorporating about 3.5 liters of water with these various additions.

Before closing up the Pod for the day I squeezed the seeds out of a number of berries, rinsed them and dried them by rubbing between paper towel to remove attached pulp. Then I photographed them before putting them into a labeled baggie. The plan is to compare the appearance of seeds before fermentation, at dryness, and at the end of extended maceration.

Friday, April 4, 2008

Pinot Fermenting In Barrel?

In a word, no. Not fast enough, anyway. Yesterday I pulled a sample from the barrel and took it in for analysis. I was hoping for that magic number of less than 1.00 g/L glucose + fructose. The lab came back this morning with 3.05 g/L, a drop of only 0.9 g/L in almost a week. It is time for me to think about re-inoculating.

Thursday, April 3, 2008

Next Ferment: Annadel Syrah

This past Tuesday I received a delivery of 3 pails of Syrah from the well-known Annadel Estate Vineyard. Well-known by me anyway. Full disclosure: I grew these grapes. These are INRA clone 877 on 101-14 rootstock, planted in 2002.

Today the pails were thawed enough to transfer the fruit to the Pod, which I had thoroughly cleaned and sanitized after pressing the Roberts Road Pinot. I dissolved 7 grams of Efferbaktol granules in one liter of water and poured 250 mL of this solution on top of the fruit in each pail.

I also made up a solution of yeast extracts: 8 g of Booster Rouge and 8 g of OptiRed suspended in another liter of water. As I poured each pail of grapes into the Pod, I followed it with about 330 mL of this suspension. Finally, I poured the last 250 mL of the Efferbaktol solution on top of the fruit in the Pod and put the lid on.

The Efferbaktol should have added about 65 ppm of SO2 to the must. The addition rates for the yeast extract products were 19 g/hL each (the maximum recommended rate for each of these products is 30 g/hL).

The Pod was reading 25° Brix at 46° F. I set the temperature control points to 50° and 53° F.

Today the pails were thawed enough to transfer the fruit to the Pod, which I had thoroughly cleaned and sanitized after pressing the Roberts Road Pinot. I dissolved 7 grams of Efferbaktol granules in one liter of water and poured 250 mL of this solution on top of the fruit in each pail.

I also made up a solution of yeast extracts: 8 g of Booster Rouge and 8 g of OptiRed suspended in another liter of water. As I poured each pail of grapes into the Pod, I followed it with about 330 mL of this suspension. Finally, I poured the last 250 mL of the Efferbaktol solution on top of the fruit in the Pod and put the lid on.

The Efferbaktol should have added about 65 ppm of SO2 to the must. The addition rates for the yeast extract products were 19 g/hL each (the maximum recommended rate for each of these products is 30 g/hL).

The Pod was reading 25° Brix at 46° F. I set the temperature control points to 50° and 53° F.

Friday, March 28, 2008

Roberts Road Pinot Analysis

Results of the analysis of the post-pressing Pinot sample:

This confirms that I did not add enough water before the start of fermentation. The alcohol is too high – some people may like wines over 15% but I find them unbalanced and fatiguing to drink – but more alarming is that the wine is not bone-dry.

My operational threshold for "dry" is 1.00 g/L (0.1% w/v, or as Vinquiry reports, 100 mg/100 mL). Some experts are OK with twice that value. But from the standpoint of assuring the most stable, most spoilage-resistant wine the only acceptable value is really "none detected". In practice, I am happy and relaxed if the residual glucose + fructose is less than 0.20 mg/L (20 mg/100 mL).

Clearly this wine is not there yet. Some guys would pitch for malolactic anyway. Not me. I want to wait for the wine to get below that 1.00 g/L threshold to make sure the bacteria produce a minimal amount of volatile acidity.

| Alcohol | 15.13 | % (v/v) |

| pH | 3.75 | |

| Titratable Acidity | 5.88 | g/L |

| Malic Acid | 1.33 | g/L |

| Glucose+Fructose | 3.94 | g/L |

| Volatile Acidity | 0.43 | g/L |

My operational threshold for "dry" is 1.00 g/L (0.1% w/v, or as Vinquiry reports, 100 mg/100 mL). Some experts are OK with twice that value. But from the standpoint of assuring the most stable, most spoilage-resistant wine the only acceptable value is really "none detected". In practice, I am happy and relaxed if the residual glucose + fructose is less than 0.20 mg/L (20 mg/100 mL).

Clearly this wine is not there yet. Some guys would pitch for malolactic anyway. Not me. I want to wait for the wine to get below that 1.00 g/L threshold to make sure the bacteria produce a minimal amount of volatile acidity.

Thursday, March 27, 2008

2007 Roberts Road Pinot Pressed

Yesterday I pressed off the Roberts Road Pinot. The Pod readings were -3° Brix and 65° F. The cap was still up and I did not mix it before starting, other than putting a hole through it with my hand to pull out the Brix sensor before installing the press ram.

The pressing went routinely. As before, I set the unit to heavy press and then switched to manual mode on completion of the auto program. In maunual pressing mode I took the ram to maximum pressure 1) every 30 seconds for 16 cycles, then 2) every 60 seconds for 9 cycles, then 3) every 5 minutes for 7 cycles.

The last two 5-minute cycles the motor tripped out immediatley, indicating I had pushed the ram down as far as it was going to go without really long waiting between cycles. This is improved performance compared to my prior pressing of the Napa River Ranch Cabernet. I attribute the difference to using enzyme on the Pinot.

Yield was about 10.8 gallons. This time I don't know exactly what the final volume was because I did not rack the wine back into the Pod after pressing, where it is easier to measure. I filled a 3-gallon carboy, filled a 30 L (7.9 gal) Vernou M+ toast barrel to within 3/4" of the bunghole, and collected about 2/3-gal of heavy lees for settling.

In my commercial production I usually press Pinot Noir to tank and then move immediately to barrels before extensive settling. I believe that the presence of the extra lees in the barrel result in increased aromatic complexity and improved mouthfeel.

Today I will take a sample to the lab for analysis. Once I confirm that the alcoholic fermentation is complete I will inoculate for malolactic in the barrel and carboy.

The pressing went routinely. As before, I set the unit to heavy press and then switched to manual mode on completion of the auto program. In maunual pressing mode I took the ram to maximum pressure 1) every 30 seconds for 16 cycles, then 2) every 60 seconds for 9 cycles, then 3) every 5 minutes for 7 cycles.

The last two 5-minute cycles the motor tripped out immediatley, indicating I had pushed the ram down as far as it was going to go without really long waiting between cycles. This is improved performance compared to my prior pressing of the Napa River Ranch Cabernet. I attribute the difference to using enzyme on the Pinot.

Yield was about 10.8 gallons. This time I don't know exactly what the final volume was because I did not rack the wine back into the Pod after pressing, where it is easier to measure. I filled a 3-gallon carboy, filled a 30 L (7.9 gal) Vernou M+ toast barrel to within 3/4" of the bunghole, and collected about 2/3-gal of heavy lees for settling.

In my commercial production I usually press Pinot Noir to tank and then move immediately to barrels before extensive settling. I believe that the presence of the extra lees in the barrel result in increased aromatic complexity and improved mouthfeel.

Today I will take a sample to the lab for analysis. Once I confirm that the alcoholic fermentation is complete I will inoculate for malolactic in the barrel and carboy.

Sunday, March 23, 2008

Inflection Point

Friday morning I worried over whether or not the fermentation would stick. I got my answer Friday afternoon, where the must readings were 0° Brix at 79° F before punchdown #11. The graph above shows a clear inflection point from the morning reading to the afternoon.

Friday morning I worried over whether or not the fermentation would stick. I got my answer Friday afternoon, where the must readings were 0° Brix at 79° F before punchdown #11. The graph above shows a clear inflection point from the morning reading to the afternoon.This sort of curve inflection indicates a second yeast population picking up as the first population slows – I have observed this inflection before when re-inoculating a sticky ferm. It appears to me that the RC212 inoculum – added at 9.5 days – took a while to pick up, but did. I also noticed that the hints of sulfide aroma I had observed in the morning were completely gone, so I did not add any DAP after all.

Friday afternoon I lowered the setpoints again, to 74° and 77° F. I made only one punch (#12) on Saturday, where the readings were -2° Brix and 73° F. Once again I dropped the setpoints, to 68° and 71° F. I also put the lid on the Pod, since the fermentation is effectively complete.

At punch #13 today, the must read -3° Brix and 68° F. I made the final adjustment to the temperature setpoints, to 66° and 69° F, where they will stay through pressing.

I am still on track to press on Wednesday the 26th as I originally planned, after 14 punchdowns and 16 days of cuvaison. Yesterday I started prepping the barrel with the first fill, and today I gave it the second filling with hot water.

Friday, March 21, 2008

Past The Peak

Wednesday night when I checked the Pinot ferment there was no evidence of Kloeckera activity (no aroma of ethyl acetate) so I went forward with my plan to inoculate the must. I rehydrated 11 grams of RC212 yeast (25 g/hL) in a mix of 200 mL distilled water plus 13 grams of GoFerm nutrient (30 g/hL) at 104° F for 20 minutes.

I added a pinch of table sugar to proof the yeast prep. To my mild dismay the inoculum foamed only very slightly. I pitched it into the must anyway with punchdown number 7, though I would have been more sanguine if the inoculum had foamed extensively. After the punch the must was down to 23° Brix at 82° F; I moved the setpoints to 88° and 91° F.

When I checked the Pod early yesterday morning the must had overflowed slightly – perhaps a fistfull of pommace and 250 mL of liquid had gone over the side. It never ceases to amaze how much of a cleanup mess is created by such a small loss.

The Pod was reading 12° Brix at 91° F. For the first time in my WinePod experience, the cooling came on during punchdown #8. I moved the setpoints to 91° and 95° F. At the afternoon punchdown (#9) the must was reading 7° Brix at 92° F and the cooling did not come on until I dropped the setpoints to 83° and 86° F.

This morning at punch #10 the Pod was registering 4° Brix at 83° F, so according to plan I further lowered the setpoints to 78° and 81° F.

So I am past the most stressful (for me) part of the ferment. The yeast may be stressed a little – there has been a whiff of sulfide at the last couple of punchdowns. If it seems that the sulfide is still present at this afternoon's punch I will probably make a very small DAP add – maybe 0.1 g/L – even though I normally prefer not to add DAP so late in the ferment.

The only worry I have left is whether the ferment is going to stick or not. The slope of the sugar curve looks fine this morning – at this time the slope suggests that it is not going to stick – but the next data point is critical. I will be reassured if the reading this afternoon is between 3° and 2° Brix. If I see a reading of 1° Brix by noon on Saturday I will be confident.

I added a pinch of table sugar to proof the yeast prep. To my mild dismay the inoculum foamed only very slightly. I pitched it into the must anyway with punchdown number 7, though I would have been more sanguine if the inoculum had foamed extensively. After the punch the must was down to 23° Brix at 82° F; I moved the setpoints to 88° and 91° F.

When I checked the Pod early yesterday morning the must had overflowed slightly – perhaps a fistfull of pommace and 250 mL of liquid had gone over the side. It never ceases to amaze how much of a cleanup mess is created by such a small loss.

The Pod was reading 12° Brix at 91° F. For the first time in my WinePod experience, the cooling came on during punchdown #8. I moved the setpoints to 91° and 95° F. At the afternoon punchdown (#9) the must was reading 7° Brix at 92° F and the cooling did not come on until I dropped the setpoints to 83° and 86° F.

This morning at punch #10 the Pod was registering 4° Brix at 83° F, so according to plan I further lowered the setpoints to 78° and 81° F.

So I am past the most stressful (for me) part of the ferment. The yeast may be stressed a little – there has been a whiff of sulfide at the last couple of punchdowns. If it seems that the sulfide is still present at this afternoon's punch I will probably make a very small DAP add – maybe 0.1 g/L – even though I normally prefer not to add DAP so late in the ferment.

The only worry I have left is whether the ferment is going to stick or not. The slope of the sugar curve looks fine this morning – at this time the slope suggests that it is not going to stick – but the next data point is critical. I will be reassured if the reading this afternoon is between 3° and 2° Brix. If I see a reading of 1° Brix by noon on Saturday I will be confident.

Wednesday, March 19, 2008

Cap Up This Morning

Yesterday afternoon I mixed the must – which was reading 25° Brix at 69° F – and increased the setpoints to 76° and 79° F. When I mixed the must (#5) I observed the first hints of incipient fermentation – a bit of foam at the edges of the tank.

This morning the cap is fully up at 75° F, though the Pod has not yet registered a drop in sugar. The ferment does not smell at all of ethyl acetate (yet).

According to plan I increased the temperature setpoints again to 81° and 84° F. I also threw in a punchdown (#6). In the Cabernet ferments I left the lid on the Pod throughout. Today I left the lid off the Pinot, and won't put it back on until the ferment is complete.

Chances are that unless I smell ethyl acetate I will inoculate with the RC212 yeast this evening. But if there is evidence of Kloeckera activity I will wait until tomorrow.

This morning the cap is fully up at 75° F, though the Pod has not yet registered a drop in sugar. The ferment does not smell at all of ethyl acetate (yet).

According to plan I increased the temperature setpoints again to 81° and 84° F. I also threw in a punchdown (#6). In the Cabernet ferments I left the lid on the Pod throughout. Today I left the lid off the Pinot, and won't put it back on until the ferment is complete.

Chances are that unless I smell ethyl acetate I will inoculate with the RC212 yeast this evening. But if there is evidence of Kloeckera activity I will wait until tomorrow.

Tuesday, March 18, 2008

Waiting For Fermentation

Yesterday evening I raised the temperature setpoints on the Pod to 64° and 67° F as planned, and gave the must a mix (punchdown #4). This morning – still no evidence of fermentation. Increased the setpoints again, to 69° and 72° F.

I'm prepared for the possibility that the ferment won't take off on its own. While I would prefer that it did, I have made great Pinot before that did not start fermenting spontaneously.

I did not have either of the Pinot yeasts I was deciding between in my commercial cache, so yesterday afternoon I picked up a brick of RC212 from Vinquiry. I decided on this yeast over the Assmanshausen (AMH), as the RC212 implants and starts fermenting quickly. By contrast, AMH exhibits a 3-5 day lag before it starts fermenting. Since I am already half way through my planned cuvaison I would rather use the yeast that kicks in fast.

I'm prepared for the possibility that the ferment won't take off on its own. While I would prefer that it did, I have made great Pinot before that did not start fermenting spontaneously.

I did not have either of the Pinot yeasts I was deciding between in my commercial cache, so yesterday afternoon I picked up a brick of RC212 from Vinquiry. I decided on this yeast over the Assmanshausen (AMH), as the RC212 implants and starts fermenting quickly. By contrast, AMH exhibits a 3-5 day lag before it starts fermenting. Since I am already half way through my planned cuvaison I would rather use the yeast that kicks in fast.

Subscribe to:

Posts (Atom)